The advantages of polymer material

Unlimited shelf life

Conventional seals become brittle when exposed to light, heat and ozone and lose their sealing capacity over time. DEPAC hydraulic seals however are made of a unique polymer material with homogeneously incorporated lubricant. They have an unlimited shelf life and can be used without problem even after a long period in storage.

Positive lip form - gentle and clean

The negative lip forms of normal seals allow dirt and foreign particles to be trapped between the seal lips and the cylinder. This causes grooving and increased repairs to the cylinder and piston rod. DEPAC's CAD-designed positive lip form wipes dirt and foreign matter away.

Without leakage, with little friction and minimum wear.

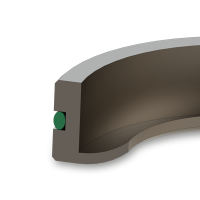

Non-absorbent polymer material

Conventional seals swell as they absorb hydraulic fluid. This causes excessive wear and filters become blocked with fibres. DEPAC’s polymer material however is not absorbent and does not swell. Its homogeneously incorporated lubricant ensures highest sliding capacity.

Installation damage is avoided

Despite the greatest of care, conventional seals are highly vulnerable to damage of the sensitive sealing faces during installation. Reduced shelf life or total failure of the seal can be the result. DEPAC’s unique polymer material prevents installation damage thanks to its high elasticity and wear-resistance.

Self-sealing – with no re-adjustment

Conventional seals often require repeated, time-consuming and therefore expensive re-adjustment to avoid excessive leakage. DEPAC’s lip-structure has inbuilt pre-tension which automatically adjusts to different pressures. There is no need for tightening or re-tightening.

Competitive prices

With modern production methods DEPAC is able to supply its entire range of seals at highly competitive prices. With the longer shelf life of the seals and the protection they give to your system, DEPAC seals represent outstanding value for money.

Short delivery times

The sometimes substantial delivery times of many hydraulic seal manufacturers increase warehouse capital for the customer. DEPAC however can guarantee supply of the most varied seal designs within just a few days.